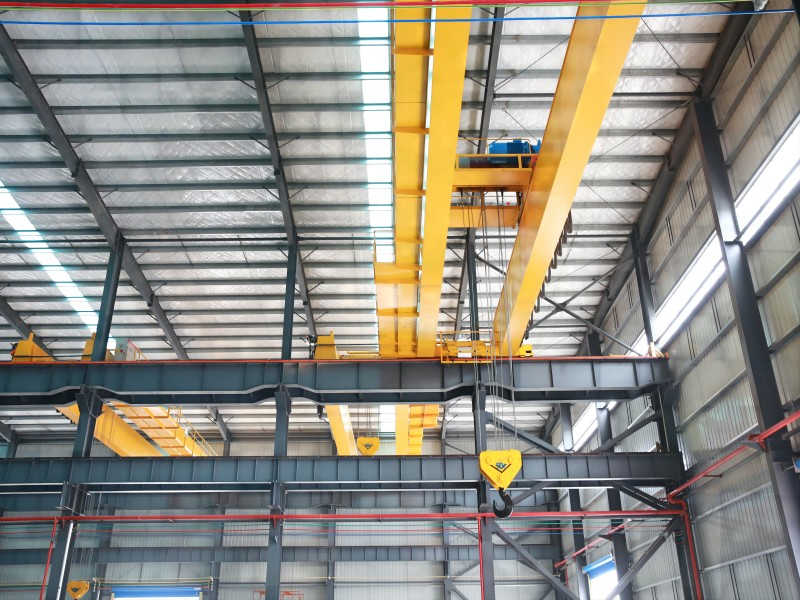

Dongqi Crane designs double-girder bridge crane for heavy industry factory

This case is a Chinese heavy industry company purchasing a bridge crane from our factory. This enterprise is mainly engaged in the manufacturing, sales and maintenance of: excavating machinery, construction engineering machinery, plastic machinery and their corresponding spare parts and components; mechanical processing.

If you want to have an in-depth understanding of our factory strength, we have prepared detailed information for customers, including product technical specifications, performance data, usage effects, customer feedback, etc. You can also communicate with us to visit the factory directly and visit the site. At the site, you can personally demonstrate the functions and performance of the product, allowing customers to experience the advantages of the product for themselves.

Parameters of a 20 ton double beam bridge crane:

Load capacity: 20 tons (maximum lifting capacity)

Span: 15 meters (distance between crane tracks)

Lifting height: 10 meters (maximum vertical distance from the ground to the lifting hook)

Working speed:

- Traveling speed of bridge crane: 20 meters/minute

- Lifting hook lifting speed: 8 meters/minute

- Car running speed: 10 meters/minute

Power requirements:

- Voltage: 400V, three-phase

- Frequency: 50Hz

- Power: Depending on specific configuration

Control method:

- Manual control: Operate the crane through the operating handle or button

- Automatic control: optional with programmable logic controller (PLC) or automation control system

Structural materials:

- Main beam: Made of high-strength steel, such as Q345B

- Lifting hooks and pulleys: Made of wear-resistant and corrosion-resistant materials

Security features:

- Overload protection: equipped with electronic overload protection device

- Limiting device: lifting hook and trolley travel limit

- Emergency braking: equipped with an emergency braking system to ensure quick stopping in emergency situations

Maintenance:

- Lubrication points: Regularly lubricate each lubrication point

- Inspection and adjustment: Regularly inspect the fasteners, wear parts, etc. of various components of the crane, and make necessary adjustments