Technical Parameters of LDY Metallurgical Electric Single Beam Overhead Crane 10t

LDY type metallurgical single beam crane is mainly used to lift molten metal in metallurgical and casting sites, and its supporting lifting mechanism is YH type metallurgical electric hoist, with lifting capacity ≤ 10t. Our small editor will share the technical parameters of 10 ton LDY type single beam metallurgical crane for your reference.

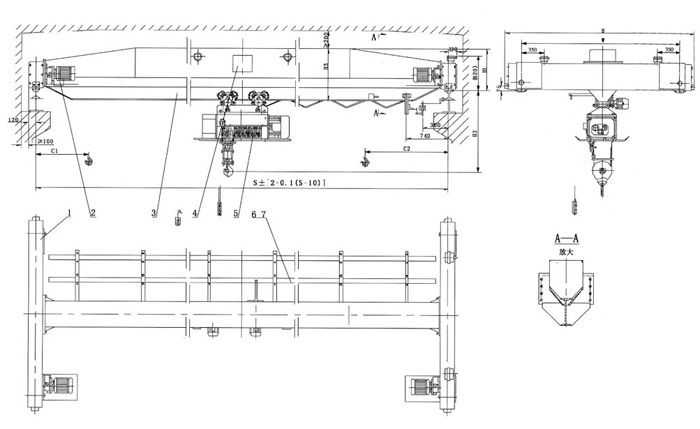

Structural drawing of metallurgical single beam crane

In the figure: 1. End beam device 2. Nameplate 3. Main beam 4. Tonnage plate 5. YH electric hoist 6. Power transmission device

Technical parameters of metallurgical single beam crane

| Crane operating structure | Running speed (m/min) | twenty | thirty | |

| speed ratio | fifty-eight point nine five | thirty-nine point four two | ||

| Motor | model | Conical cage | ||

| Power (kw) | 0.8×2、1.5×2 | |||

| Speed (r/min) | one thousand three hundred and eighty | |||

| Lifting structure (electric hoist) And operation structure | Electric hoist type | YH | ||

| Lifting speed (m/min) | 8(7) | |||

| Lifting height H (m) | 9、12、15、18、20 | |||

| Movement speed (m/min) | twenty | |||

| Motor | Conical cage | |||

| working system | Intermediate JE=20% | |||

| Power Supply | 380V 50HZ | |||

| Wheel diameter | 270 400 | |||

| Track surface width | 37-70 | |||

Parameter table of 10t single beam metallurgical crane

| 吨位(t) | 跨度(m) | 整车总量(t)地操 | 最大轮压(kN) | 最小轮压(kN) | 踏面至主梁顶H1 | 踏面至钩中心H2 | 主梁总高H3 | 端梁轮距W | 端梁总长B | 吊钩左极限C1 | 吊钩有极限C2 |

| 10 | 7.5 | 3.55 | 50.8 | 6.5 | 820 | 1780 | 1000 | 2000 | 2500 | 15001 | 2100 |

| 8 | 3.63 | 51.7 | 6.6 | ||||||||

| 8.5 | 3.72 | 52.6 | 6.8 | ||||||||

| 9 | 3.81 | 53.4 | 7.0 | ||||||||

| 9.5 | 3.90 | 54.1 | 7.2 | ||||||||

| 10 | 3.99 | 54.7 | 7.4 | ||||||||

| 10.5 | 4.07 | 55.4 | 7.6 | ||||||||

| 11 | 4.16 | 56.0 | 7.7 | ||||||||

| 11.5 | 4.39 | 56.9 | 8.3 | 1825 | 1100 | ||||||

| 12 | 4.48 | 57.4 | 8.5 | ||||||||

| 12.5 | 4.58 | 57.9 | 8.7 | ||||||||

| 13 | 4.67 | 58.4 | 8.9 | ||||||||

| 13.5 | 4.76 | 58.9 | 9.1 | ||||||||

| 14 | 4.86 | 59.3 | 9.4 | ||||||||

| 14.5 | 5.15 | 60.3 | 10.1 | 1865 | 1140 | 2500 | 3000 | ||||

| 15 | 5.24 | 60.7 | 10.3 | ||||||||

| 15.5 | 5.34 | 61.1 | 10.5 | ||||||||

| 16 | 5.44 | 61.6 | 108 | ||||||||

| 16.5 | 5.54 | 62.0 | 11.0 | ||||||||

| 17 | 5.64 | 62.4 | 11.2 | ||||||||

| 17.5 | 6.44 | 64.5 | 13.2 | 925 | 1925 | 1250 | |||||

| 18 | 6.55 | 64.9 | 13.5 | ||||||||

| 18.5 | 6.67 | 65.3 | 13.8 | ||||||||

| 19 | 6.79 | 65.8 | 14.1 | ||||||||

| 19.5 | 6.91 | 66.2 | 14.4 | ||||||||

| 20 | 8.31 | 69.8 | 17.9 | 1100 | 1850 | 1350 | 3000 | 3500 | |||

| 20.5 | 8.46 | 70.3 | 18.2 | ||||||||

| 21 | 8.61 | 70.7 | 18.6 | ||||||||

| 22.5 | 8.76 | 71.2 | 18.9 |