KBK cranes become the ideal choice in various industrial fields

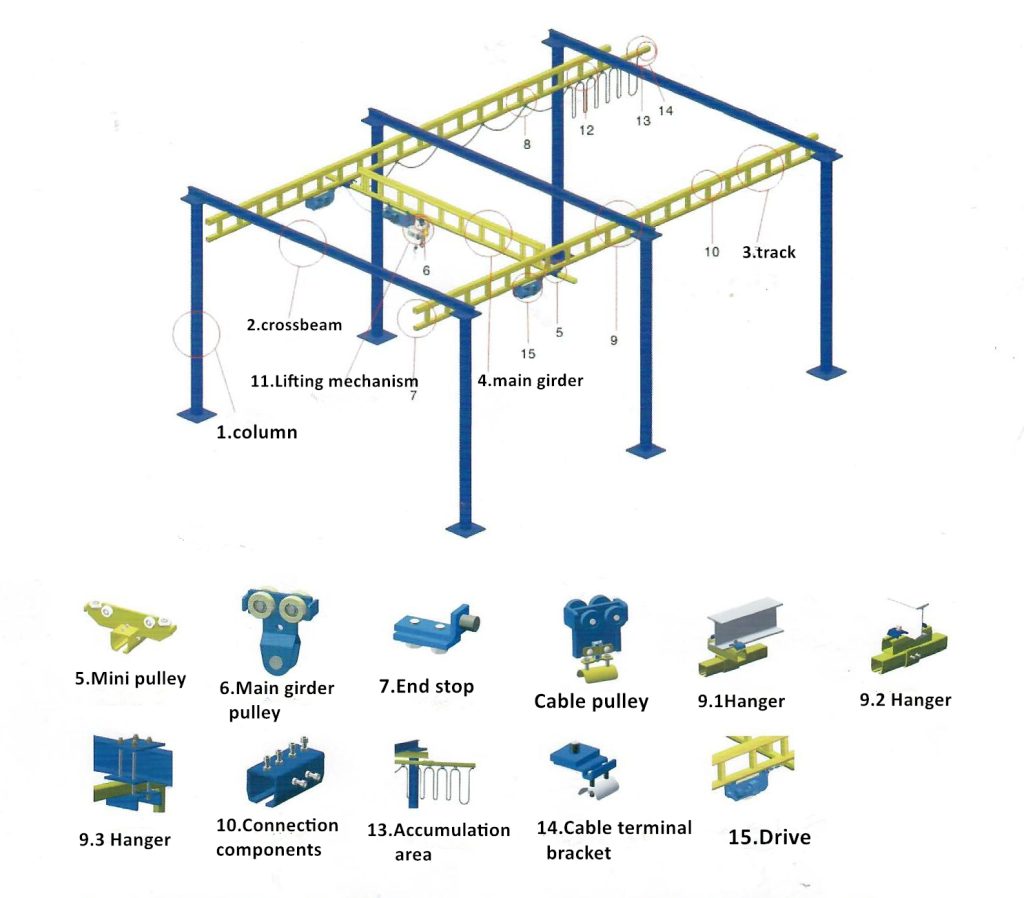

KBK, the abbreviation of German Kombiniert Kran, means modular crane. It is a patented product of DEMAG (the patent period has expired), which was later imitated or designed by various crane manufacturers. Mainly composed of track, suspension device, walking trolley and some functional components, all modules are standard components. The hoisting device mainly adopts electric chain hoist, and can also hang some manipulators or welding guns, which can be used as tool slides. The lifting weight is generally up to 2000kg.

KBK track-use Ω shape, 2 pieces welded together. Commonly used is the KBKII type track, and multiple tracks can be connected by high-strength bolts. The turning radius of the curved rail is 1.5m, and straight rails can be used for large bends. There is no smaller radius, which will affect the operation of the trolley. (The turning radius of the KBKI track is 1m, so I won’t introduce it here). It is also possible to install a built-in sliding contact wire on the inside of the KBKII track for power supply by the hoist, which is called the KBKII-R type.

The suspension device can generally be installed on the lower edge of the I-beam/H-beam, with a certain self-locking function, and the installation is simple and reliable.

Functional components include: switch, cross turntable, lifting section, etc.

- KBK combination cranes include various types of lifting equipment, such as monorail cranes, single beam cranes, double beam cranes, telescopic beams, and stackers. The lifting capacity is 0.125t~2t and has a wide range of applications, especially suitable for modernization. The characteristics of the production conveyor line are summarized as follows:

- Good reliability and high stability. All the components of the KBK light crane system are standard modules, which can ensure mass and high-quality production, so the system is very reliable; the main body of the system module is three specifications of cold-rolled profiles with high strength , Good rigidity, light weight, ensuring the stability of the system.

- Strong adaptability. The KBK system can flexibly design and install the crane system according to the needs of each station in the factory. From fixed-point transportation to high-accuracy multi-point and multi-beat automatic conveyor lines, it can be combined at will. It can be used in newly designed workshops, and can also be used in the transformation or extension of old systems.

- Easy to install, cost-effective and efficient. The installation and debugging of the KBK system is very convenient. The profiles and standard modules can be used only by bolt connection, which can save the space and area of the factory, greatly reduce human resources, and improve production efficiency. Reduce energy consumption and improve corporate efficiency. The system can be operated manually, or it can realize automatic and semi-automatic operation with high efficiency.

Advantages of KBK cranes

- Flexibility and customizability: KBK cranes adopt a modular design and are highly flexible and customizable. Whether in a large logistics warehouse or a small production workshop, KBK cranes can be customized according to the size of the work space to meet the requirements of special working environments. This flexibility allows the crane to adapt to different workplaces and needs, providing more options for lifting scenarios.

- High precision and efficiency: KBK cranes have a high-precision positioning system that can accurately place parts into the hands of workers. This high-precision positioning system allows the crane to greatly reduce the labor intensity of workers and improve assembly efficiency during the assembly process. In addition, KBK cranes also adopt advanced suspension systems and control systems, making them more stable during operation and improving work efficiency.

- Lightweight design and easy installation: KBK cranes adopt a lightweight design, making the overall weight of the equipment lighter and easier to transport and install. This not only reduces the cost of the equipment but also increases its flexibility. At the same time, the installation of the KBK crane is also very simple, and the track can be installed quickly, reducing installation costs and time.

- High reliability and stability: KBK cranes use high-quality materials and components, and undergo strict testing and inspection to ensure the reliability and stability of the equipment. This allows KBK cranes to maintain stable performance even under long-term continuous operation, reducing equipment failures and maintenance costs.

How to choose KBK crane?

KBK crane is actually a series, which belongs to a kind of suspended single beam, but does not use I-beam, but mostly uses C-shaped steel and hanging parts combination. The structure is relatively simple. However, the load-bearing capacity is limited, and chain hoists are generally used for lifting.

The KBK system crane includes various types of lifting equipment such as KBK-D single track, KBK-LD single beam, KBK-LS double beam, KBK-LSS telescopic beam, KBK-LM stacker, etc. The lifting capacity is 0.125t~2t. It has a very wide range, especially suitable for modern production conveyor lines. Its characteristics are summarized as follows:

- Good reliability and high stability. All the components of the KBK light crane system are standard modules, which can ensure mass and high-quality production, so the system is very reliable; the main body of the system module is three specifications of cold-rolled profiles with high strength , Good rigidity, light weight, ensuring the stability of the system.

- Strong adaptability. The KBK system can flexibly design and install crane systems according to the needs of each station in the factory. From fixed-point transportation to high-accuracy multi-point and multi-beat automatic conveyor lines, it can be combined at will. It can be used in newly designed workshops, and can also be used in the transformation or extension of old systems.

- Easy to install, cost-effective and efficient. The installation and debugging of the KBK system is very convenient. The profiles and standard modules can be used only by bolting, which can save the space and area of the factory, greatly reduce human resources, and improve production efficiency. Reduce energy consumption and improve corporate efficiency. The system can be operated manually, or it can realize automatic and semi-automatic operation with high efficiency.