Crane Hook

The crane hook is one of the most important components in crane operations, and its quality and safety requirements are very high. When selecting and using crane hooks, factors such as the equipment’s carrying capacity, usage environment, shape and weight of the items to be lifted must be taken into consideration to ensure that the lifting task is completed safely and reliably.

Dongqi Crane can supply various types of crane hooks to Malaysian customers. We have rich manufacturing experience and technical strength, advanced production technology and strict quality control system to ensure that every hook meets international standards and customer requirements.

Our hook products are available in a variety of models, specifications and uses, suitable for various types of cranes and working conditions. We focus on product research and development and innovation, constantly launch new products that meet market needs, and provide comprehensive solutions for the crane industry.

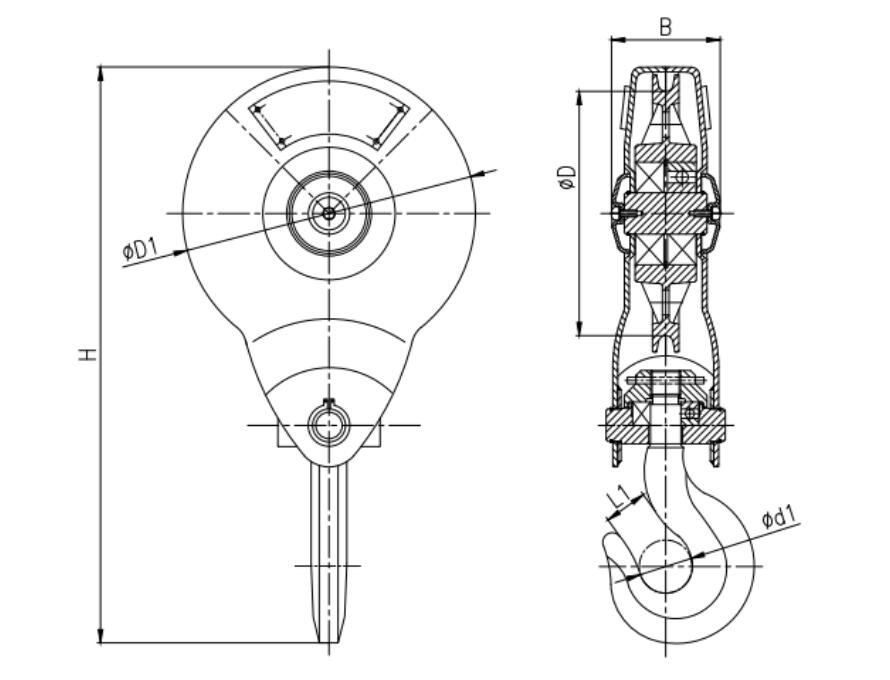

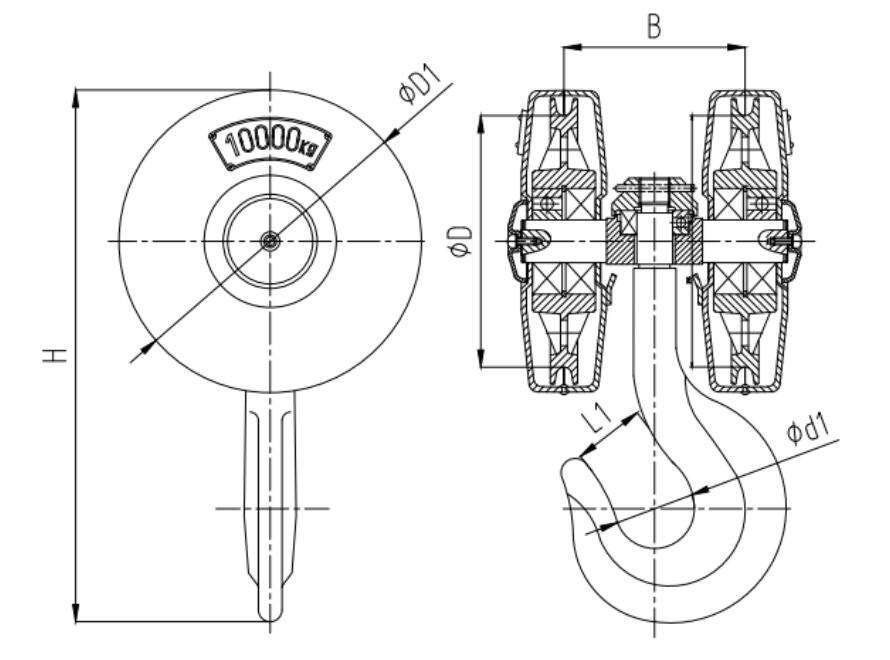

Crane Hook Drawing

Features

Hook often bears the impact of shock and cutting load in the working process,so hook material should have either enough strength or better toughness. Forging hook material adopts high-quality low carbon killed steel or low carbon alloy steel, such as 20 high-quality low carbon steel, 16Mn、20MnSi、36MnSi, which is annealed after being forged. Manufacturing is simple and it is easy to operate, but stress condition is bad so it is mainly used in the workplace below 80t lifting capacity. When lifting capacity is big, force symmetry double hooks are adopted. There are single hook and double hooks about strap type hook. Strap type hook is made up of hook chips which is punched and sheared from 16Mn steel plate of thickness no less than 20mm, and then riveted by rivets.When materials are unloaded, height direction of board hook and direction of steel plate rolling are the same, which can improve strength of hook. In order to make load uniformly distribute into every chip, and reduce abrasion of wire rope. Disconnectable base plates are set at the mouth of hook.

When individual plate has flaws, the whole hook is not damaged. The safety is good, but dead weight is big. Therefore, it is mainly equipped with big lifting capacity cranes or cranes lifting molten steel ladles.