Double Girder EOT Crane Design – Mechanical Parts

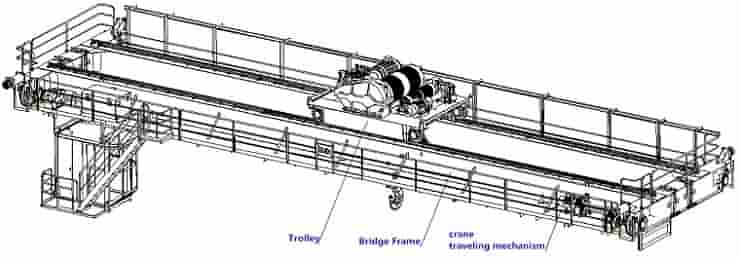

1. Double Girder EOT Crane trolley is composed of one set or two sets of (main, Aux.) lifting system, traveling mechanism, structural frame, etc.

2. Double Girder EOT Crane main beam, side beam and trolley frame material adopt Q345-B, main beam fatigue calculation in strict accordance with working level A5, steel plate must be treated with shot blasting, weld joint must be inspected, web height direction are not allowed splicing.

3. Double Girder EOT Crane bridge frame and trolley frame fitting with lifting position, easy to replace the wheel.

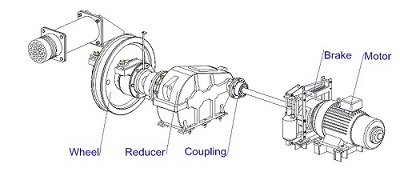

4. Double Girder EOT Crane long traveling wheel adopt double wheel rim type, surface hardness is HB320-380 after forming wheel machining; quenching hardened layer side depth not less than 15mm, surface hardness not less than HB320 in 15mm depth.

5. Reducer requires sealing, dust proof, set observation hole, air vent and drain hole in the upper.

6. The bridge end beam should be set with sliding block frame; overhaul cage is located at the collector.

7. Double Girder EOT Crane all major steel structure surface treated with shot blasting, sand-blasting grade reached Sa2.5 level.

8. Safety railings, columns, ladders, handrails production according to related standard, the relative height of the railing is 1050mm, spacing of 400mm, railings can withstand 1KN forces from all directions without plastic deformation.

9. Double Girder EOT Crane driver’s cabin requires fully enclosed, with tempered glass, allow sufficient maintenance space, with comfortable adjustable seats, door locks, fire extinguishers and alarms, etc. The laying of the floor surface with non-conducting and non-skid pads. All windows can be safely cleaned, and can install from inside the cabin.

10. Double Girder EOT Crane body color: paint dry film total thickness not less than 120um. Finishing coat is uniform, fine, bright, complete and consistent color. Safety railings painted yellow and black safety colors.